A thread gauge is used to check the dimensions of a specific thread form angle, pitch and diameter.

Plug gauges are used to check internal threads, whereas ring gauges are used to check external threads.

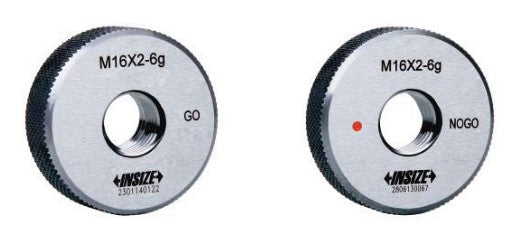

Each gauge comprises of two parts: a GO gauge and a NO GO gauge. Both parts should be used to check the thread.

If you are machining a component with an external thread – you would use both a GO and a NO GO ring gauge. The GO gauge will screw on to the part. The NO GO gauge should not screw on to the part.

For a thread to be within its permissible dimensions, a GO plug gauge should screw into an internal thread and a NO GO should not screw into it.

Thread Gauges

UNC Class 2A Go/No Go Ring Gauges | Insize 4121 Series

£42.00

The Insize 4121 Thread Ring gauges for gauging outside thread, to determine if the thread is within the upper/lower limits of the components tolerance. The size and form can be determined by using go and no go rings. Made from hardened alloy steel for longer tool life and durability from machine shop wear. Go and No-Go are supplied separately. ...

UNF Class 2A Go/No Go Ring Gauges | Insize 4121 Series

£92.00

The Insize 4121 Thread Ring gauges for gauging outside thread, to determine if the thread is within the upper/lower limits of the components tolerance. The size & form can be determined by using go and no go rings. Made from hardened alloy steel for longer tool life and durability from machine shop wear. Go and No-Go are supplied separately...